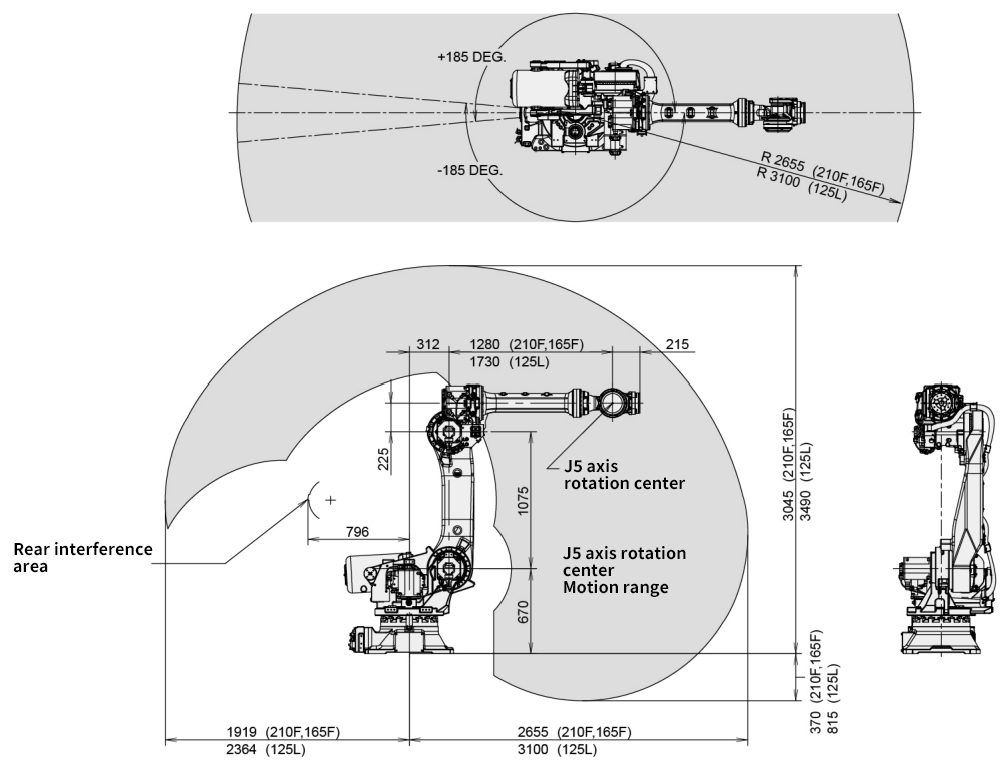

Model | R-2000iC/210F | R-2000iC/165F | R-2000iC/125L |

Mechanism | Multi-jointed robot |

Number of controlled axes | 6 axes (J1, J2, J3, J4, J5, J6) |

Reachable radius | 2655 mm | 3100 mm |

Installation | Ground installation |

Range of motion

(maximum speed)

Note 1)

| J1 axis rotation | 370°(120/s)6.46 rad(2.09 rad/s) | 370°(130/s)6.46 rad(2.27 rad/s) |

J2 axis rotation | 136°(105%s)2.37 rad(1.83 rad/s) | 136°(115%s)2.37 rad(2.01 rad/s) |

J3 axis rotation | 312°(110°%s)5.45 rad(1.92 rad/s) | 312°(125°/s)5.45 rad(2.18 rad/s) | 301°(125°/s)5.25 rad(2.18 rad/s) |

J4 axis wrist rotation | 720°(140/s)12.57 rad(2.44 rad/s) | 720°(180°/s)12.57 rad(3.14 rad/s) |

J5-axis wrist swing | 250°(140%s)4.36 rad(2.44 rad/s) | 250°(180/s)4.36 rad(3.14 rad/s) |

J6-axis wrist rotation | 720°(220°%s)12.57 rad(3.84 rad/s) | 720°(260%/s)12.57 rad(4.54 rad/s) |

Wrist load capacity | 210 kg | 165 kg | 125 kg |

J2 machine base can handle mass | 550 kg | 550 kg | 550 kg |

J3 arm can carry mass | 25 kg(A) | (A)+(B)≤50kg | 25 kg(A) | (A)+(B)≤50kg | 25 kg(C) | (C)+(D)≤40kg |

J3 housing can handle mass | 50 kg(B) | 50 kg(B) | 40 kg(D) |

Wrist allowable load torque | J4 axis | 1360 N ·m 139 kgf ·m | 940 N ·m 96 kgf m | 710 N ·m 72 kgf-m |

J5 axis | 1360 N-m 139 kgf m | 940 N ·m 96 kgf ·m | 710 N ·m 72 kgf-m |

J6 axis | 735 N ·m 75 kgf ·m | 490 N ·m 50 kgf ·m | 355 N ·m 36 kgf m |

Wrist allowable load Moment of inertia | J4 axis | 147 kg ·m 1500 kaf cm · s2 | 89 kg ·m 908 kgf ·cm · s | 72 kg ·m 735 kgf:cm · s |

J5 axis | 147 kg ·m 1500 kgf ·cm · s2 | 89 kg ·m 908 kgf ·cm · s | 72 kg ·m 735 kgf ·cm · s |

J6 axis | 82 kg m 837 kgf ·cm · s | 46 kg ·m2 469 kgf cm · s | 40 kg ·m² 408 kgf cm · s2 |

Drive mode | Electrical servo drive using AC servo motors |

Repeatability (Note 2) | ±0.05mm |

Robot Quality Note 3) | 1090 kg | 1090 kg | 1115 kg |

Installation conditions | Ambient temperature: 0 ~ 45℃

Ambient humidity: usually below 75%RH (no condensation)

Short-term below 95%RH (within 1 month)

Vibration acceleration: below 4.9m/s² (0.5G)

|

Note 1) When moving a short distance, the maximum speed of each axis may not be achieved. |

Note 2) The measurement results are in accordance with ISO 9283 “Industrial robots performance specifications and test methods”. |

Note 3) Control device part is not included. |