Model | R-1000iA180F | R-10001iA100F | R-1000iA/130F | R-1000iA/80H |

Mechanism | Articulated Robot |

Number of controlled axes | 6-axis(J1、J2、J3、J4、J5、J6) | 5-axis(J1、J2、J3、J4、J5) |

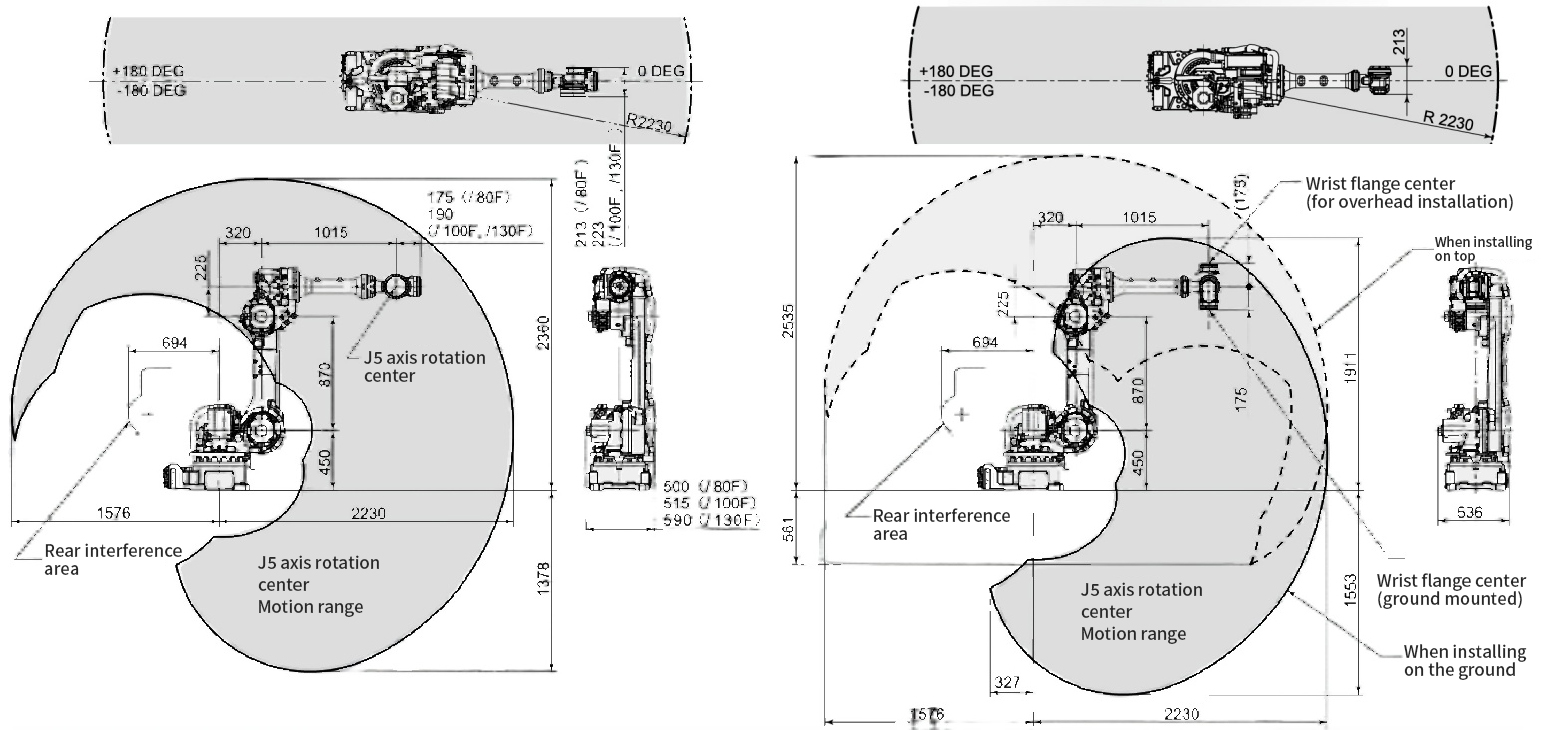

Reachable radius | 2230 mm |

Installation | Ground installation, ceiling installation |

Range of motion (maximum speed) Note 1) | J1 axis rotation | 360°(170°/s)6.28 rad(2.97 rad/s) | 360°(130°/s)6.28 rad(2.27 rad/s) | 360°(130°/s)6.28rad(2.27rad/s) | 360°(185°/s)6.28 rad(3.23 rad/s) |

J2 axis rotation | 245°(140°/s)4.28 rad(2.44 rad/s) | 245°(110°/s)4.28 rad(1.92 rad/s) | 245°(110°/s)4.28rad(1.92rad/s) | 245°(180°/s)4.28 rad(3.14 rad/s) |

J3 axis rotation | 360°(160°/s)6.28 rad(2.79 rad/s) | 360°(120°/s)6.28 rad(2.09 rad/s) | 360°(120°/s)6.28rad(2.09rad/s) | 215°(180°/s)3.75 rad(3.14 rad/s) |

J4-axis wrist rotation (/80H: wrist swing) | 720°(230°/s)12.57 rad(4.01 rad/s) | 720°(170°/s)12.57 rad(2.97 rad/s) | 720°(170°/s)12.57rad(2.97rad/s) | 20°(180°/s)0.35 rad(3.14 rad/s)

Note 2) |

J5 axis wrist rotation

(80H: wrist rotation)

| 250°(230°%s)4.36 rad(4.01 rad/s) | 250°(170°/s)4.36 rad(2.97 rad/s) | 250°(170°/s)4.36rad(2.97rad/s) | 720°(500°/s)12.57 rad(8.73 rad/s) |

J6-axis wrist rotation | 720°(350°/s)12.57 rad(6.11 rad/s) | 720°(250°/s)12.57 rad(4.36 rad/s) | 720°(250°/s)12.57rad(4.36rad/s) | |

Wrist load capacity | 80 kg(A) | (A)+(B)<80kg | 100 kg | 130 kg | 80 kg(A) | (A)+(B)<80kg |

J3 arm can carry mass | | 20 kg(C) | 20 kg(C) | |

J3 base part can carry mass | 15 kg(B) | 20 kg(D) (C)+(D)<20kg | 20 kg (D) (C)+(D)<20kg | 15 kg(B) |

Wrist allowable load torque | J 4 axis | 380 N ·m 38.8 kgf ·m | 690 N ·m 70.4 kgf m | 800 N ·m 81.6 kgf m | Note 3) |

J 5 axis | 380 N ·m 38.8 kgf ·m | 690 N ·m 70.4 kgf-m | 800 Nm 81.6 kgf m |

J 6 axis | 200 N ·m 20.4 kgf m | 260 N ·m 26.5 kgf m | 360 N ·m 36.7 kgf m | |

Wrist allowable load Moment of inertia | J 4 axis | 30 kg ·m²306.1 kgf cm ·s² | 57 kg ·m²581.6 kgf cm ·s² | 71 kg ·m²724.5 kgf-cm ·s² | 48 kg ·m²489.8 kgf-cm ·s² |

J5 axis | 30 kg ·m²306.1 kgf cm ·s² | 57 kg ·m²581.6 kgf cm ·s² | 71 kg ·m²724.5 kgf cm ·s² | 25 kg m² 255.1 kgf cm ·s² |

J 6 axis | 20 kg ·m²204.1 kgf cm ·s² | 32 kg ·m²326.5 kgf cm ·s² | 38 kg ·m²387.8 kgf-cm ·s² | |

Drive mode | Electrical servo drive using AC servo motors |

Repeatability Note 4) | ±0.03 mm |

Robot Quality Note 5) | 620 kg | 665 kg 675 kg | 610 kg |

Installation conditions | Ambient temperature: 0~45℃

Ambient humidity: usually below 75%RH (no condensation)

Short-term below 95%RH (within 1 month)

Vibration acceleration: below 4.9m/s²(0.5G)

|

Note 1) The maximum speed may not be achieved when moving short distances. |

Note 2) The wrist flange is always kept in a downward position by controlling the wrist angle. The wrist flange tilt angle can be fine-tuned within a maximum range of ±10°. |

Note 3) The maximum distance from the center of the wrist flange to the center of gravity of the load is limited by the wrist load and inertia.

When the wrist load and inertia reach their maximum values, the maximum allowable distance from the center of gravity of the load to the center of the wrist flange is 254mm in the horizontal direction and 400mm in the vertical direction.

|

Note 4) Conforms to ISO 9283. |

Note 5) Does not include control device part. |