CRX-5iA | CRX-10iA CRX-10iA/L CRX-20iA/L CRX-25iA |

Number of controlled axes | 6-axis(J1、J2、J3、J4、J5、J6) |

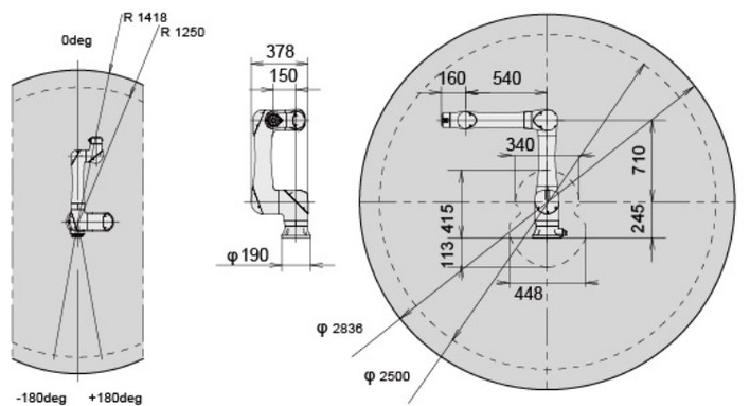

Reachable radius | 994 mm | 1249 mm 1418 mm | 1889 mm |

Installation method (Note 1) | Ground installation, ceiling installation, tilt angle installation |

Range of motion

(maximum speed)

(Note 2) | J 1 axis | 400°(150%s)6.8Fad(262radls) | 380°(120%s)6.63rad (2.09rad/s)360°(120%5)6.28 ad(2.09radls) | 360°(80°%)6.28 ad(140radls) | 360°(80%s)628 ad(140 rads |

J 2 axis | 360°(150%s)628 rad (2.62 rad/s) | 360°(120°/s)6.28 rad (2.09 rad/s) | 360°(80%s)6.28 rad (1.40 rad/s) | 360°(80%s)6.28 rad(1.40 rad/s) |

J 3 axis | 635°(180%s)11.08 rad(3.14 radls) | 57[ (180%s)9.95 rad (3.14 rad/s)540°(180%s)9.42 rad (3.14 rad/s) | 540°(120%s)9.42rad(2.09rad/s) | 540°(120%s)9.42rad(2.09 rad/s) |

J 4 axis | 380°(225%s)6.63 rad (3.93 rad/s) | 380°(180°/s)6.63 rad (3.14 rad/s) | 380°(112/s)6.63 rad(1.95rads) | 380°(180%s)6.63 rad(3.14rad/s) |

J 5 axis | 360°(225%s)6.28 rad (3.93 rad/s) | 360°(180°/s)6.28 rad (3.14 rad/s) | 360°(90%s)6.28 rad (1.57 rad/s) | 360°(180%s)6.28 rad (3.14 rad/s) |

J 6 axis | 450°(225%s)7.85 rad (4.45rad/s) | 450°(180°/s)7.85 rad (3.14 rad/s) | | 450°(112/s)7.85 rad(1.95 rad/s)450°(180%s)7.85rad (3.14rad/s) |

Maximum speed (Note 2,3) | Collaborative Mode | 1000 mm/s |

High-speed mode | 2000 mm/s | 1000 mm/s | 2000 mm/s |

Wrist load capacity | 5 kg | 10 kg | 20 kg | 25 kg |

Permissible load torque of wrist | J 4 axis | 19.0 Nm | 348 Nm | 70.0 Nm | 100.0 Nm |

J 5 axis | 15.4 Nm | 26.0 Nm | 64.0 Nm | 74.0 Nm |

J 6 axis | 6.7 Nm | 11.0 Nm | 30.0 Nm | 32.0 Nm |

Wrist allowable load Moment of inertia | J 4 axis | 0.77 kg-m² | 1.28 kg-m² | 4.00 kg-m² | 4.70 kg-m² |

J 5 axis | 0.50 kg-m² | 0.90 kg-m² | 4.00 kg-m² | 4.00 kg-m² |

J 6 axis | 0.10 kg-m² | 0.30 kg-m² | 2.00 kg-m² | 2.00 kg-m² |

Repeatability (Note 4) | ±0.03 mm | ±0.04 mm | ±0.05 mm |

Robot quality (note 5) | 25 kg | 40 kg | 41 kg | 135 kg |

Robot protection level | IP67 |

Installation conditions | Ambient temperature: 0~45℃ Ambient humidity: usually below 75%RH (no condensation) | Vibration acceleration: 4.9m/s² (0.5G) or less Short-term 95% RH or less (within one month) |

Control device R-30iB Mini Plus | Power supply | AC100~120V, AC200~240V single phase, 50/60Hz |

Quality | 20 kg | 22 kg |

Dimensions (width x depth x height) | 410×277×370 mm |

Protection level | IP54 |

TP cable | 5m、10m、20m | |

RCC Cable Specifications | 1m, 4m, 7m, 14m (the main body comes with 1.5m, which can be combined to a maximum length of 18m) 1m、4m、7m、14m |

Optional communication method | EtherNet/IP,EtherNetIP safety adapter,PROFINET,PROFINET safety,CC-link,FL-net safety,

EtherCAT slave,DeviceNet,CC-link IE FIELD,PROFIBUS,DeviceNet safety |

Note 1) When the machine is installed at an inclined angle, the range of motion may be limited depending on the load mass. | Note 2) The maximum speed may not be achieved when moving short distances. | |

Note 3) The speed of action needs to be determined based on the risk assessment of the system. | Note 4) Complies with ISO9283 standard. | |

Note 5) The mass of the control device is not included. | | |