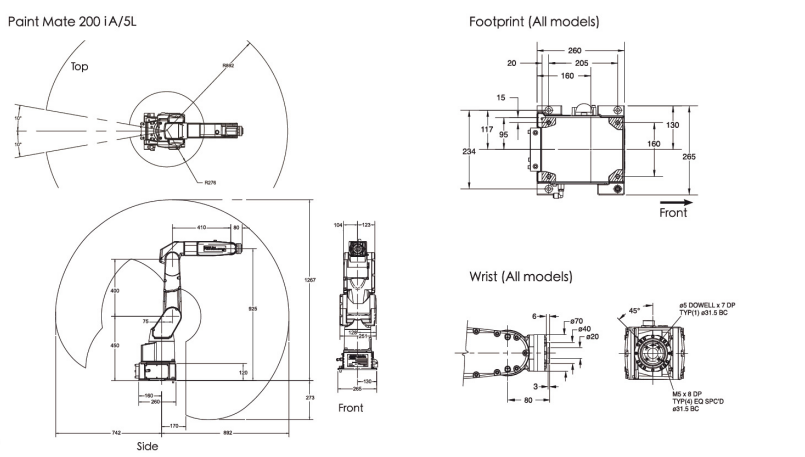

Basic description: Fanuc Robot PaintMate is a compact painting robot driven by a servo motor. It has the best performance among similar products in the world and is suitable for use in hazardous environments. Mainly used for: spraying, painting, assembly and handling in hazardous environments, gluing

Features and advantages:

iPendant is a color teaching pendant with Internet access for easy programming and customizable user interface

One or four built-in solenoid valves on the scavenging module can control the switch gun and automatic cleaning (optional)

Various installation methods such as floor mounting, inverted mounting, wall mounting, etc. are suitable for small spraying spaces

Absolute pulse encoder ensures that the origin does not need to be recalculated after power-on

Standard FANUC robot scavenging control

FM and ATEX explosion-proof certification ensures that it can be used in Class 1, ll and Ill Div.1 environments

Slim arms and small bases facilitate installation in small environments

High acceleration and high deceleration motion characteristics can shorten the work cycle

Reliable safety circuit control

Maintenance features:

Latest generation design

Fully sealed bearings and brushless AC motors

Specialized scavenging modules

Designed for harsh environments

Software:

Two application software can be used

①, Handling Tool™ can achieve basic settings, programming and control, and the built-in macro program includes a spray application plug-in, which is convenient for those who know how to use Handling Tool™ users can master the spraying application in a short time.

②、Paint Tool™ realizes the following spraying function control for single machine or multi-robot system:

Analog parameter control

Automatic color change

Two-component paint supply gear pump control

Closed-loop flow control

Online synchronous tracking

Collision protection

Internet connection

KAREL programming language

Process control hardware needs to be increased accordingly