Features

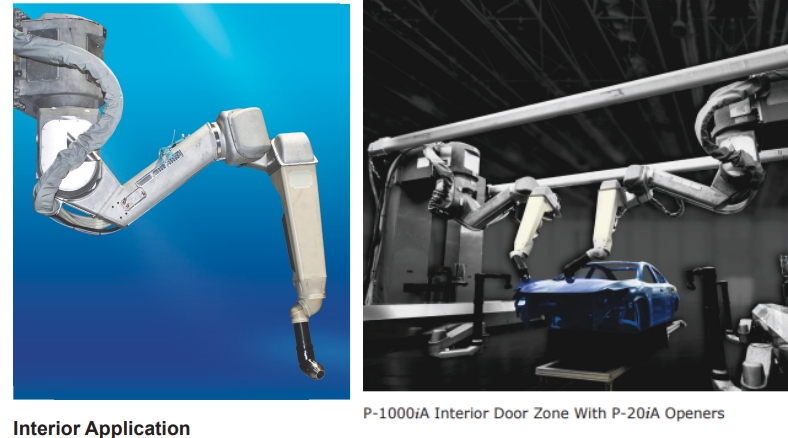

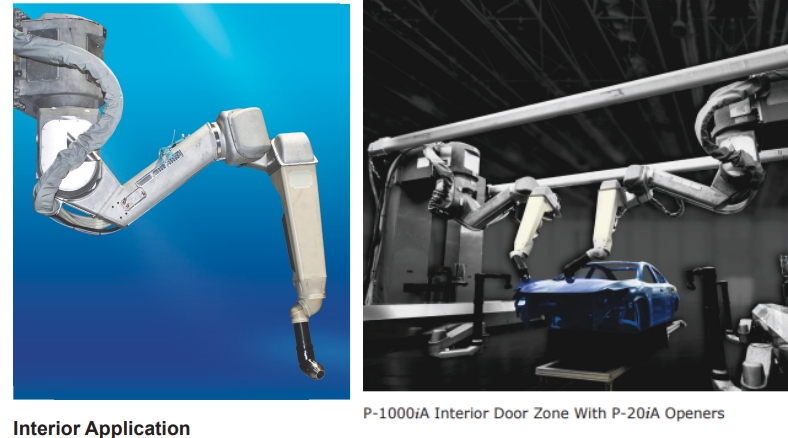

Design:

Unique Painting Robot With Seven Integrated Axes

Optimally Position Arm In Interior & Exterior Paint Programs

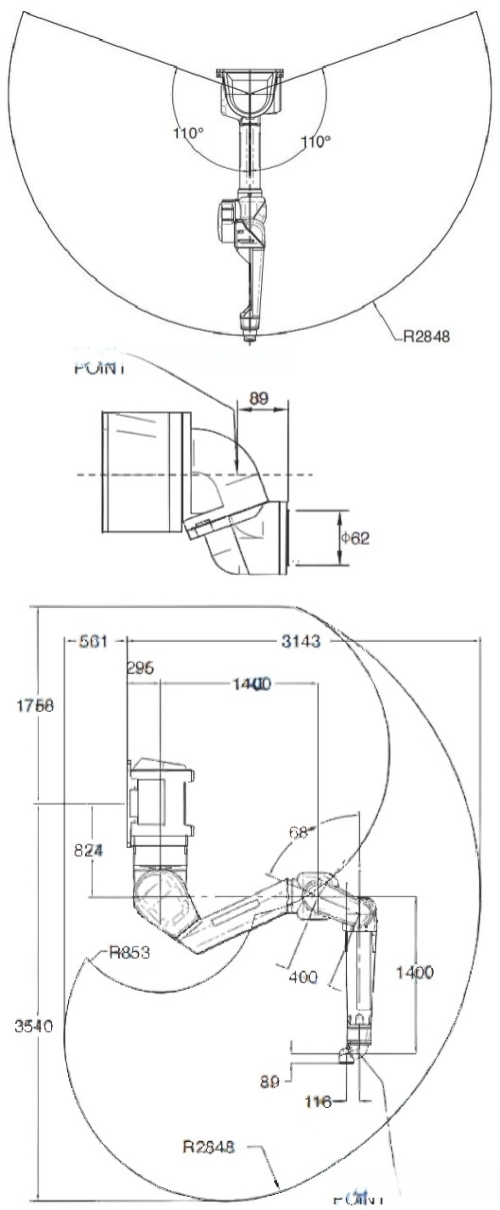

Inverted Pedestal Installation Maximizing Work Envelop

Balanced Arm Length Provides Excellent Near & Far Reach

Payload Supports A Range Of Rotary Atomizers & Spray Guns

Booth:

Minimizes Booth Size By Optimizing Robot Density

In-Line Arms Maintain Process Symmetry Across The Booth

Application:

Easy Access To All Critical Process Components

Maximized Performance With In Arm Process Components

Integrated Fluid Delivery Systems WithFANUC Servo Motors

Direct Charge Waterborne And 1k & 2k SolventborneSystems

140°Hollow Wrist Optimized For Demanding Paint Processes

Controller:

A Compact And StackableR-30iB Paint Controller

Single Arm And Dual Arm Controller Support

Supported By The iPendant Color Graphical Teach Pendant

Integrated Support Of Hood, Deck And Door Opener Controls

Supports All Major Network Communications Protocols

Software Features

Paint Application:

Industry's Most Powerful & Easy-To-Use Interface - PaintTool

Integrated Diagnostic Monitoring And Reporting Of Process

Parameters Provides Real-Time Strip Chart Capability

Motion Enhancement

Software Functionality To Simplify Elbow Position Control

Dual Check Safety Enables Smaller Booths

Collision Guard Minimizes Application Equipment Damage

Options:

Mechanical Unit & Paint Process Equipment Are Monitored And Protected By FANUC's Zero Down Time Package

Pressure vs. Flow Monitoring Software Detects Fluid Delivery System Problems In Real-Time

ROBOGUIDE PaintPRO Offline 3D Programming