Product IntroductionRoboticsIRB 1100 The most compact and fastest robot in its classThe IRB 1100 further expands ABB's small robot product line, increasing productivity by 35% and reducing floor space by 10%.

Outstanding performance, high-quality production

Designed to improve manufacturing productivity, the IRB 1100 can reduce cycle time by 35%, and its leading repeatability ensures high-quality manufacturing.

Compared to similar robots, the IRB 1100 can achieve higher payload and repeatability (RP) even in limited space. In fact, the IRB 1100 has the highest payload in its class.

Compact and flexible installation

Compared with previous generations of robots, the IRB 1100 robot design has been optimized to reduce floor space by 10% and reduce weight by more than 20%, allowing it to be installed in a variety of production environments such as electronic manufacturing plants to achieve efficient use of space.

The small footprint means that multiple robots can be deployed simultaneously to perform automated operations in collaboration, and more flexible heavy-load operations can be achieved with complex tools/end effectors.

IRB 1100 supports ABB's new OmniCore™ controller with advanced motion control capabilities, making it ideal for fast assembly, pick and place and material handling.

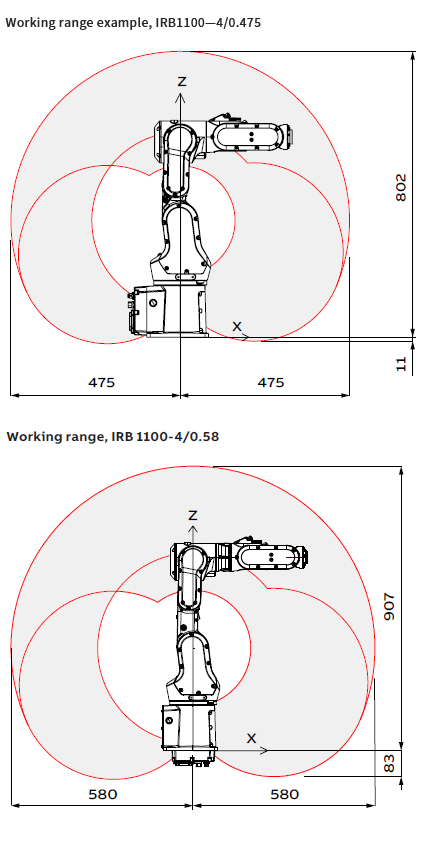

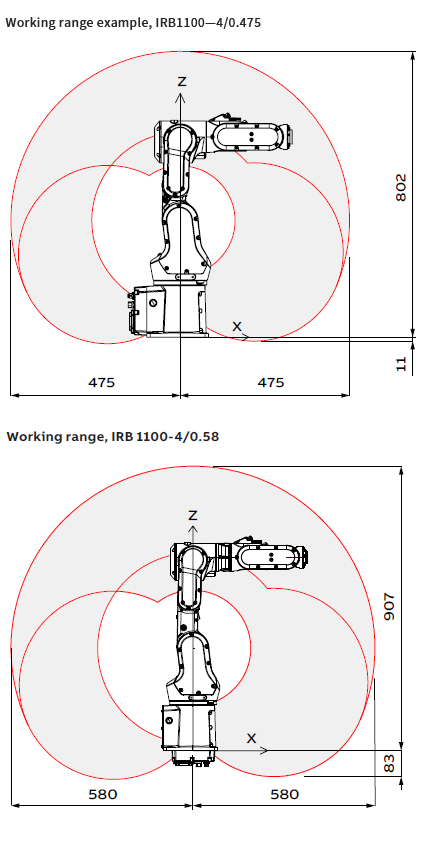

ABB will also launch a cleanroom version of the IRB 1100 in the future. In addition, the IRB 1100 robot is available in two models: one with a payload capacity of 4 kg and a reach of 475 mm; the other with a payload capacity of 4 kg and a reach of 580 mm.

Main advantages:

· Offers 35% faster cycle times for increased productivity

· 10% smaller footprint, more than 20% lighter weight, flexible and easy installation

· Highest payload among similar robots

· Up to 16 inputs/outputs for more sophisticated applications

Main applications:

· Assembly and testing

· Loading and unloading

· Screwing

· Inserting rubber