RoboticsIRB 5500 FlexPainter

A new way to spray externally

The IRB 5500 FlexPainter combines spray equipment in one for better coating quality. The robot

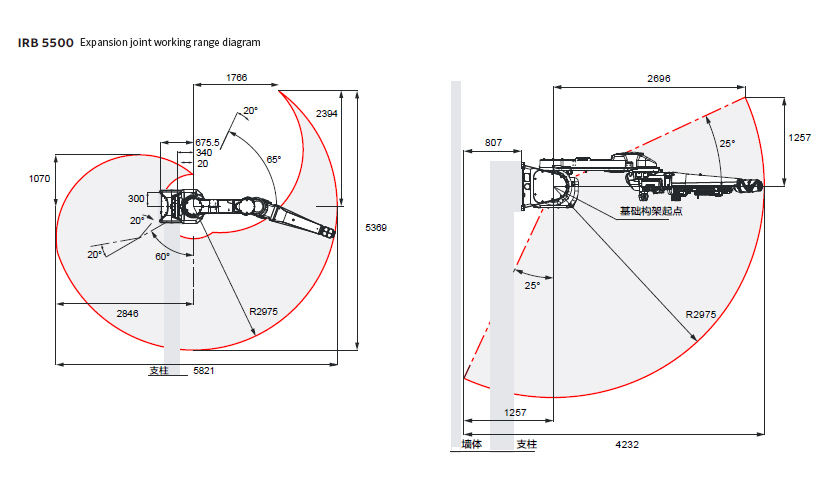

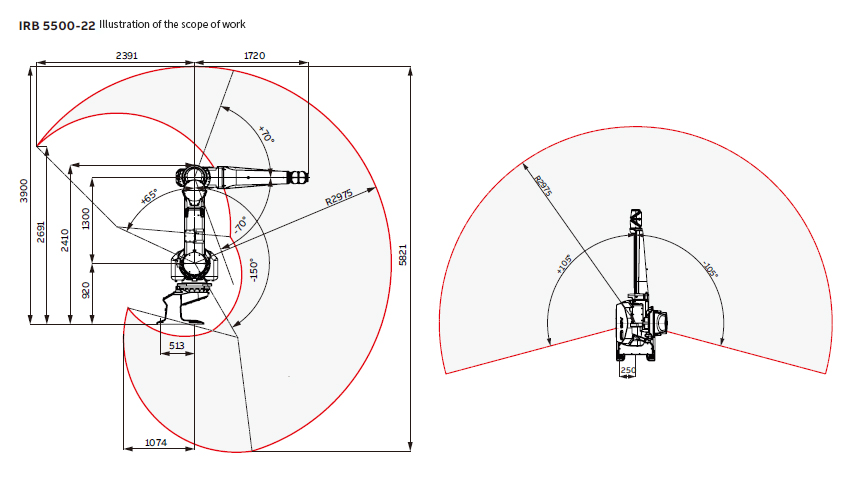

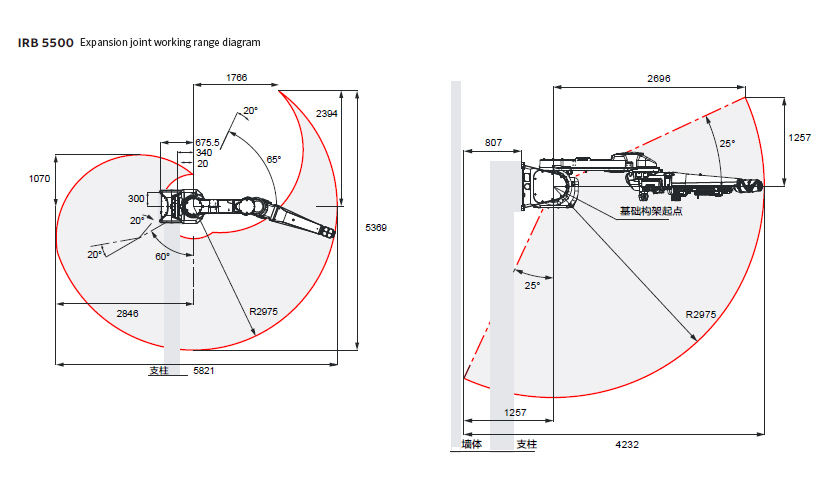

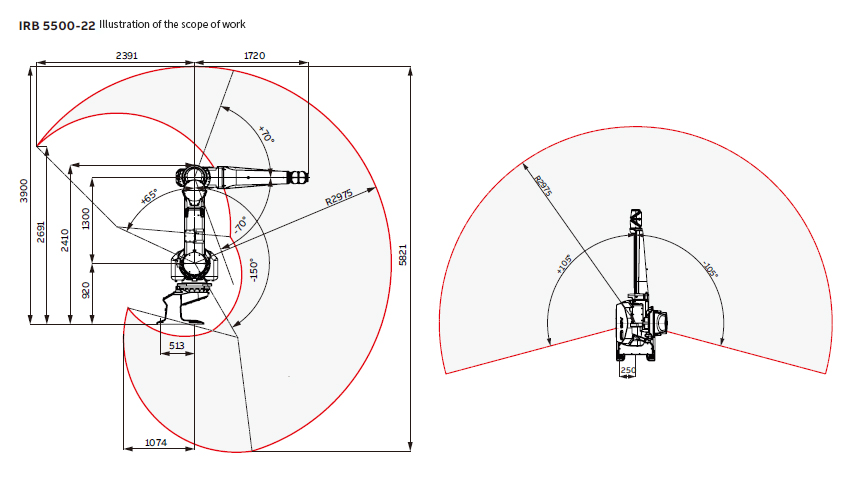

With its large working range, excellent acceleration and high spraying speed, it is a flexible and efficient solution for almost any application.

Saves paintThanks to its compact and lightweight design, key paint conditioning equipment such as the gear pump can be installed only 15 cm from the wrist, which significantly reduces paint and solvent losses during color changes.

In addition to the fully integrated process control (hardware and software), the IRB 5500FlexPainter also combines process equipment in one. The IRC5P controls the spraying process and the robot movements, which can significantly save spray material.

Based on IPS technologyThe IPS system integrates a push-out function for further paint savings. The basic architecture of IPS combines process control with motion control, which simplifies system setup and enables real savings and improved processes.

Tailor-made for sprayingThe standard solution robot process arm is equipped with up to 32* color change valves. In addition, two gear pumps driven by integrated servomotors, 64 pilot valves, atomizer control with dual shaping air and closed-loop regulation, closed-loop regulation of cup speed, and high-pressure control are fully integrated. The above solutions are applicable to both solvent-based and water-based paints, and more solutions can be provided on special request.

Fewer atomizers, more flowABB's high-flow RB1000 atomizer series is a supporting product designed specifically for the high acceleration/high-speed operation characteristics of the IRB 5500FlexPainter. The combination of the two is like adding wings to a tiger, reducing the number of robots in the spray room and achieving excellent operating performance and coating quality.

Modular spraying componentsTo achieve the process integration of the IRB 5500FlexPainter, ABB has developed a series of lightweight, compact and modular spraying components, including color change valves, two-component mixers, air and paint regulating valves and gear pumps. All components are designed for maximum flow.

Spraying robot control systemIRC5P is a modern control system tailored for spray workshops. The system, equipped with the Integrated Process System (IPS), the user-friendly, explosion-proof certified FlexPaint teach pendant and RobView 5, combines standardized features of spray equipment to meet specific needs. The system package includes standard applications for defining user interfaces, program editing, version control and more. RobView 5 can also be used as a part of a larger studio control HMI such as ABB FlexUI.

*Note

01 IRB 5500-22 Process Robot / Overhead Mount

02 IRB 5500-22 Process Robot / Floor Mount

03 IRB 5500-23 Process Robot / Cleaning Wall Rail