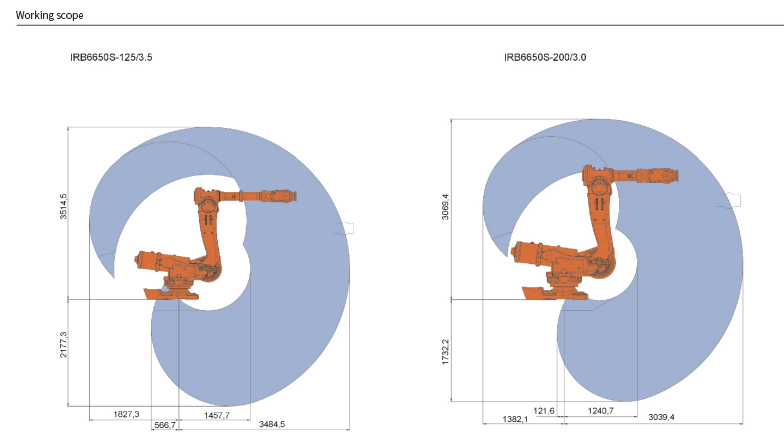

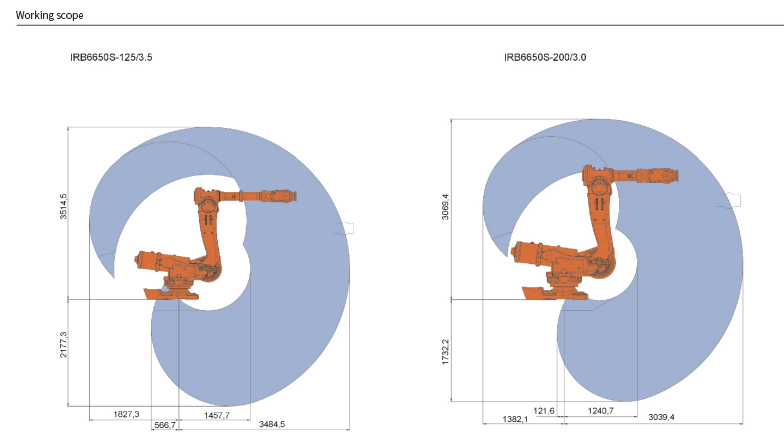

IRB 6650S is a frame robot in the power robot series. It provides a unique working range, can be used for full vertical and horizontal movement, and its front and lower working range is also larger, further enriching the robot's functions in many application fields.Product Features· High reliability - long uptime· High safety - safe investment· Fast speed - short operation cycle time· High precision - stable quality of parts production· High power - wide range of applications· Rugged and durable - suitable for harsh production environments· Versatile - flexible integration and productionMain features

The IRB 6650S offers stable operation, high production uptime, short cycle times, high performance and high utilization. It is mainly used in applications such as loading and unloading, material handling, spot welding and die casting.

Material handling

The IRB 6650S can be mounted on overhead rails, with an extended front and lower working range, to monitor feed conveyors for parts of different sizes, and can monitor twice as many conveyors as a five-axis or six-axis robot mounted on traditional hanging or wall-mounted rails. Compared with a five-axis robot mounted on an inverted rail, the IRB 6650S can significantly shorten the rail length, thus simplifying installation and reducing total costs.

Injection molding

The IRB 6650S is particularly suitable for large injection molding machines over 1,000 tons. This six-axis robot has a high degree of flexibility, which is conducive to post-process operations such as flame treatment and assembly.

Die Casting

The IRB 6650S is well suited for die casting and parts handling due to its unique working range. The process cables are embedded in the robot arm and are fully protected, which greatly extends the service life.

Spot Welding

Another advantage of the IRB 6650S is that the robot can be installed at different heights, further increasing the density of robot layout in the body assembly station. The standard version of the IRB 6700 robot can be installed on the floor, while the IRB 6650S can be installed at a height of about 1.5m to 2m above the ground.

With this layout, the standard version of the robot can perform spot welding work on the lower part of the body, while the IRB 6650S is responsible for spot welding work on the upper part of the body, thus greatly improving the space utilization of the body assembly station.

Press Loading and Unloading

The IRB 6650S can handle very large plates, such as the entire body side. The increased working range allows the robot to be withdrawn from the press even when carrying large fixtures and parts. Excellent acceleration performance combined with leading horizontal and vertical travel significantly shortens the cycle time of the IRB 6650S, further increasing productivity. The working area under the IRB 6650S facilitates fast fixture changes.

LeanID DressPack

The IRB 6650S can be equipped with the optional LeanID DressPack, which enhances the possibility of complex wrist movements in processes that require high flexibility, such as changing products.Main applications:

·Loading and unloading

·Material handling

·Spot welding

·Die casting