Robot Model | Working scope(m) | Carrying capacity

(kg) |

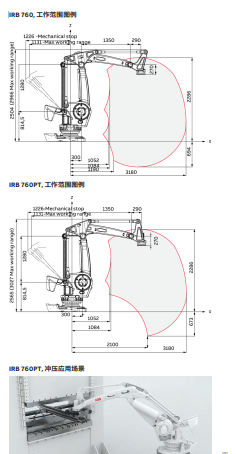

IRB 760 | 3.18 | 4.5 |

IRB 760PT | 3.18 | 4.5 |

Number of axes | 4 |

Protection level | IP67 |

Installation | Landing |

Controller | IRC5 single cabinet controller, IRC5 dual cabinet controller |

Signal and power | Optional |

Gas Source | Optional |

Performance (Compliant with I50 9283) |

| Repeat positioning accuracy

RP(mm) | Repeat path accuracy

RT(mm) |

IRB 760 | 0.05 | 0.8 |

Beats per hour | |

| Load(kg) | Beats per hour |

IRB760 | 60 | 450 |

Technical Information |

Electrical Connections | |

Supply voltage | 200-600V50-60Hz |

Power consumption | ISO cube 2.75 kw |

Physical properties | |

Robot base size | 1140mmx800 mm |

Robot weight | 2310 kg |

Environment |

Mechanical part ambient temperature | |

Runtime | +-0°C(32°F) to +50°C (122°F) |

During transportation and storage | -25° C(-13° F) to +55° C(131°F) |

Within a short period of time (no more than 24 hours) | Up to +70°C (158°F) |

Relative humidity | Up to 95% |

Noise level | <70 dB(A) |

Safety | Dual circuit with monitoring, emergency stop and safety functions, 3-position enabling device |

Radiation | EMC/EMI Shielding |

Data and dimensions are subject to change without prior notice |

Sports | |

Axis movement | Working scope | Top speed |

Axis 1 | +180° to -180° | 85°/s |

Axis 2 | +85° to -42° | 85°/s |

Axis 3 | +120° to -20° | 85°/s |

Axis 4* | +300° to -300° | 160°/s |

*Maximum +GT to -67 rpm |

Safety | |

Basics | Safety emergency stop Dual channel safety circuit 3 position starter with monitoring function |

Electronic limit switch | 5 safety outputs (monitoring axes 1-7) |

SafeMove | Standstill, speed, position and direction monitoring (robot and additional axes) 8 safety inputs (function enabled) 8 monitoring outputs |

Mechanical interface | |

Input/Output | Up to 4096 signals |

Number | 24V DC or relay signal |

Simulation | 2x0-10V |

Serial Port | 1xRS 232/RS 422 |

Network | Ethernet (10/100 MB/S), service channel and LAN channel |

Dual Channel | PROFINET

PROFIBUS DP

EtherNeMPM

DeviceNet™ |

Fieldbus Master | PROFINET

PROFIBUS DP

EtherNetP™

Interbus

Allen-Bradley Remote I/O

CC-Link |

Process Encoder | Up to 6 channels |

Process interface | Robot upper arm signal interface Control cabinet reserves space for additional equipment |

Sensor interface | |

Search stop (automatic program switching)

Weld seam tracking Contour tracking

Conveyor chain tracking

Machine vision system force control

|

Data and dimensions subject to change without notice. |

Security | |

Basics | Safety stop, emergency stop 2-channel safety circuit monitoring 3-position start device |

Mechanical interface | |

Input/Output: | Standard 16/16 (up to 8192) |

Number: | 24VDC or relay signal |

Simulation: | 1*0-10V |

Serial Channel: | 1xRS232 (RS422 with adapter) |

Network | Ethernet (10/100 MB/s) |

Two channels: | Services and LAN |

Fieldbus(Master): | DeviceNetP

ROFINET

PROFIBUS DP

Ethernet/IP™ |

Fieldbus (slave): | PROFINET

PROFIBUS DP

Ethernet/IPM

Interbus

Allen-Bradley Remote I/O

CC-Iink |

Processing encoder | Up to 6 channels |

Sensor interface | |

Search stop (with automatic program switching)

Conveyor chain tracking Machine vision system Weld seam tracking

|

Data and dimensions are subject to change without prior notice |