IRB 2600ID industrial robots save space and increase capacity in arc welding, material handling and loading and unloading applications.ABBIRB 2600ID-15/1.85IRB 2600ID robotHigh payload/large reach/integrated cablesThe IRB 2600ID robot series has high payload and large reach, and uses integrated cable (ID) technology. All cables are embedded in the upper arm and wrist, which reduces cycle time by 15% and significantly increases capacity in various applications.

Product Features and Benefits

The IRB 2600ID industrial robot saves space and increases capacity in arc welding, material handling, and loading and unloading applications. This model uses integrated matching (ID) technology and expands the working range, which can reduce arc welding cycle time by up to 15% and reduce floor space costs by 75%. IRB 2600ID is available in two models: 15 kg load, 1.85 m reach; 8 kg load, 2.0 m reach.

The IRB 2600ID can significantly reduce cycle time and enhance production reliability. All pipelines are firmly fixed and their movements are easy to predict, so that programming and simulation can accurately reflect the operating status of the robot system, greatly improving programming speed and reliability. Because the pipeline swing is very small, the robot can always maintain the highest acceleration.

The service life of the pipeline is greatly extended. All pipelines are properly fastened and protected, which not only reduces the swing during operation, but also effectively prevents the erosion of welding spatter and cutting fluid.

The compact design of IRB 2600ID, no loose pipelines, and extremely small footprint create favorable conditions for high-density and high-capacity operations. For the same production workstation, the number of IRB 2600ID installations can be increased by 50%, and the maximum production capacity can be increased by 50%. The IRB 2600ID with integrated matching technology has a slender wrist and can perform complex movements even in narrow spaces.

Taking arc welding as an example, the IRB 2600ID can perform high-quality circular welding without interruption, greatly shortening the cycle time.Main application areas

· Loading and unloading

· Material handling

· Arc welding

IRC5 controller

Power input: 200-600v, 50-60Hz

Dimensions: 970*725*710mm

Weight: 150kg

Protection level: IP54

Control hardware: multi-processing system, pci bus, large-capacity flash disk, power failure backup power supply, USB storage interface

FlexPendant teaching pendant

Weight: 1kg

Support: color touch screen, joystick emergency stop, support left/right hand switching

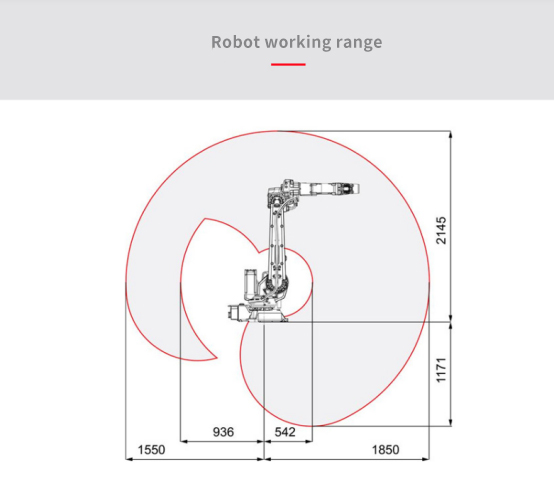

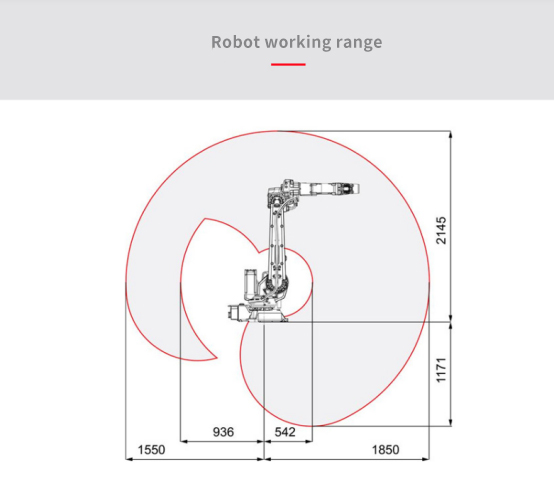

Support USB flash drive, hot swap, recovery program USB storage support, login with time stamp, support remote service Robot working range:

Robot working range: