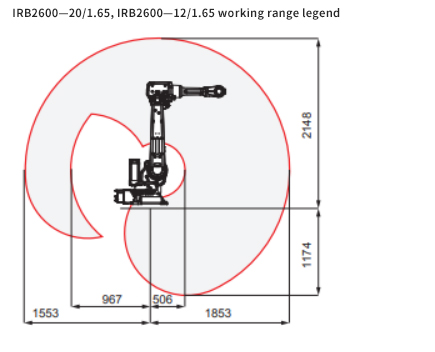

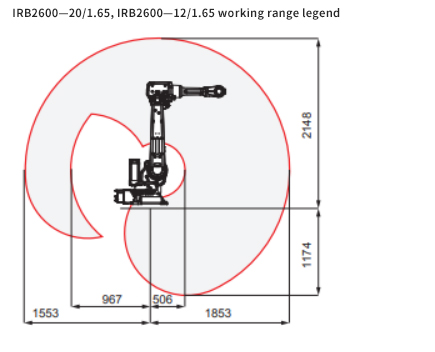

ABBIRB 2600-12/1.85ABBFurther expansion of mid-range robot seriesMain applications: arc welding. Assembly. Material handling. Loading and unloading. Material removal. Cleaning/spraying. Gluing. PackagingThe second model of the "Sharp Generation" robot, IRB 2600, is launched with enhanced innovative functions. This model has a compact body, strong load capacity, and optimized design, suitable for target applications such as arc welding, material handling, loading and unloading. Three sub-models are available, with flexible installation methods such as floor-standing, wall-mounted, bracket, inclined, and inverted.The IRB 2600 family includes 3 sub-models with loads ranging from 12kg to 20kg. This family of products is designed to improve the productivity of loading and unloading, material handling, arc welding and other processing applications.Main features and uses of the productThe new compact design allows the robot to carry a maximum load of 20 kg and optimizes its working range in material handling, loading and unloading, and arc welding applications. IRB 2600 has the highest accuracy and acceleration in its class, ensuring high output and low scrap rate to improve productivity.

Flexible installation methods: including floor mounting, inclined mounting, wall mounting, inverted mounting and bracket mounting, which help to reduce the footprint and increase the effective application of equipment. The performance of wall mounting is particularly significant. These features make the design of the workstation more creative and optimize the footprint of the robot in various industrial fields and applications.