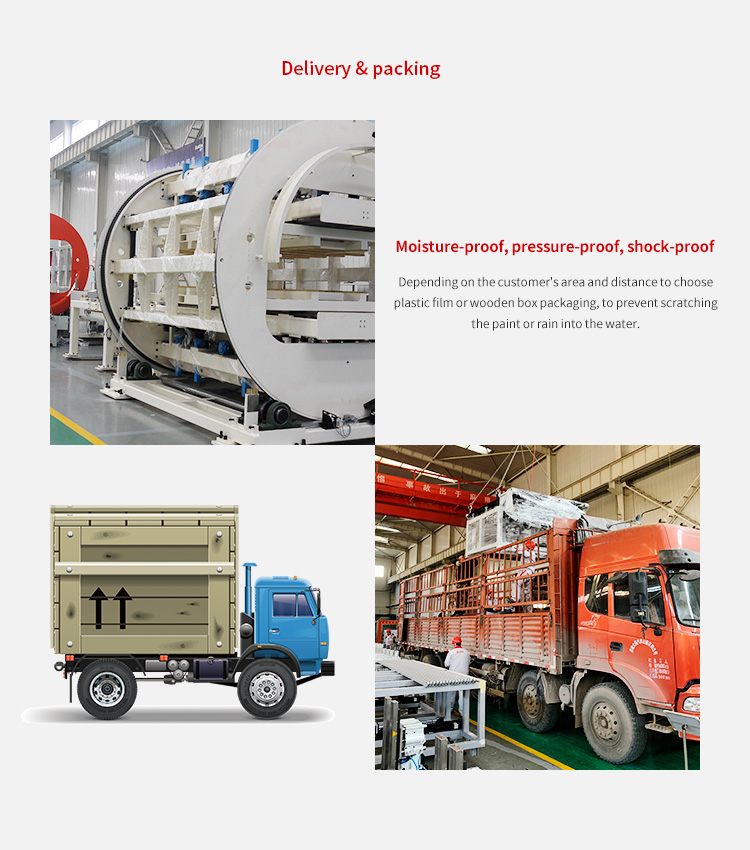

Warm reminder: Once this product is ordered, it will not be returned unless it has quality issues!Special note: Product images and parameters are slightly different from the actual product.Customization instructions: All specifications are tailored according to the customer's actual situation or after inspection, and non-standard customization is supported.Stock delivery: In stock

Product introduction:

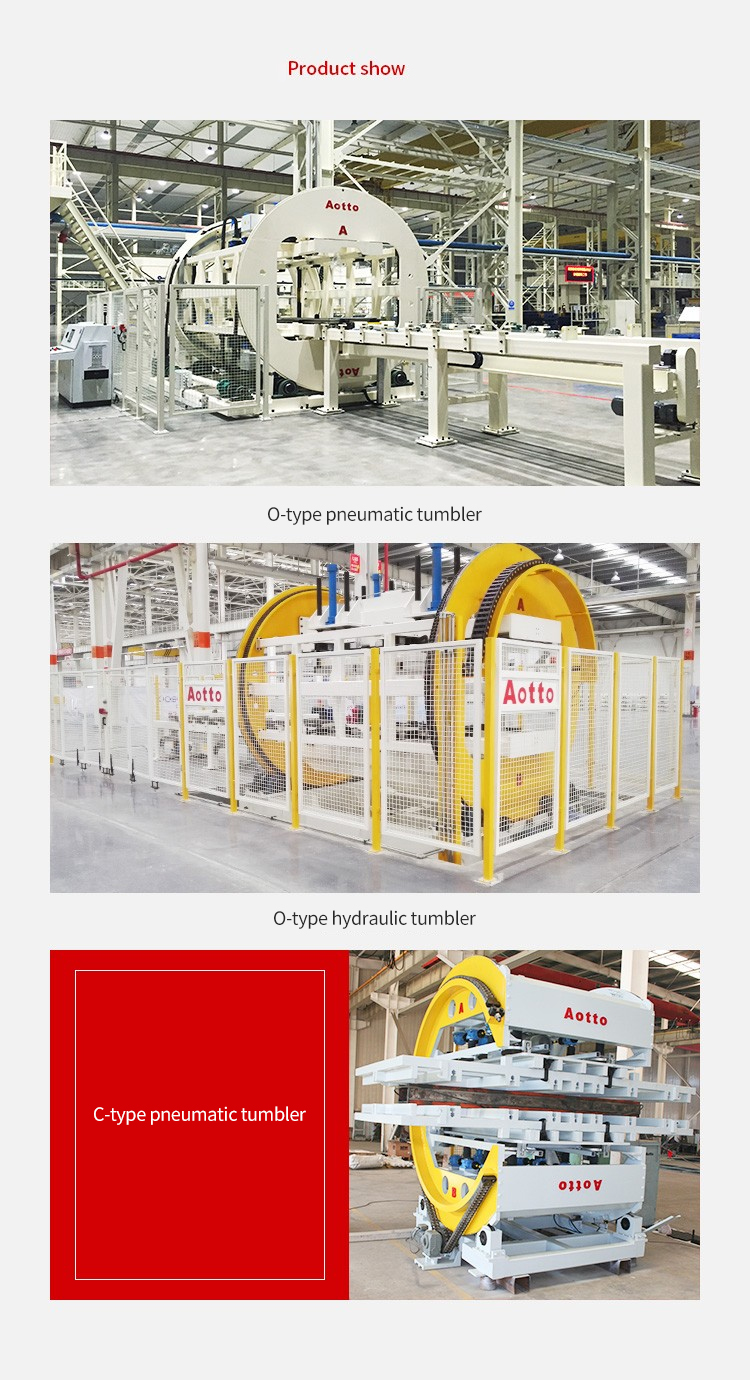

ABT series stack turning machine is a special equipment for turning over a whole stack of sheet materials. It is suitable for various industries such as automobile production and steel distribution.

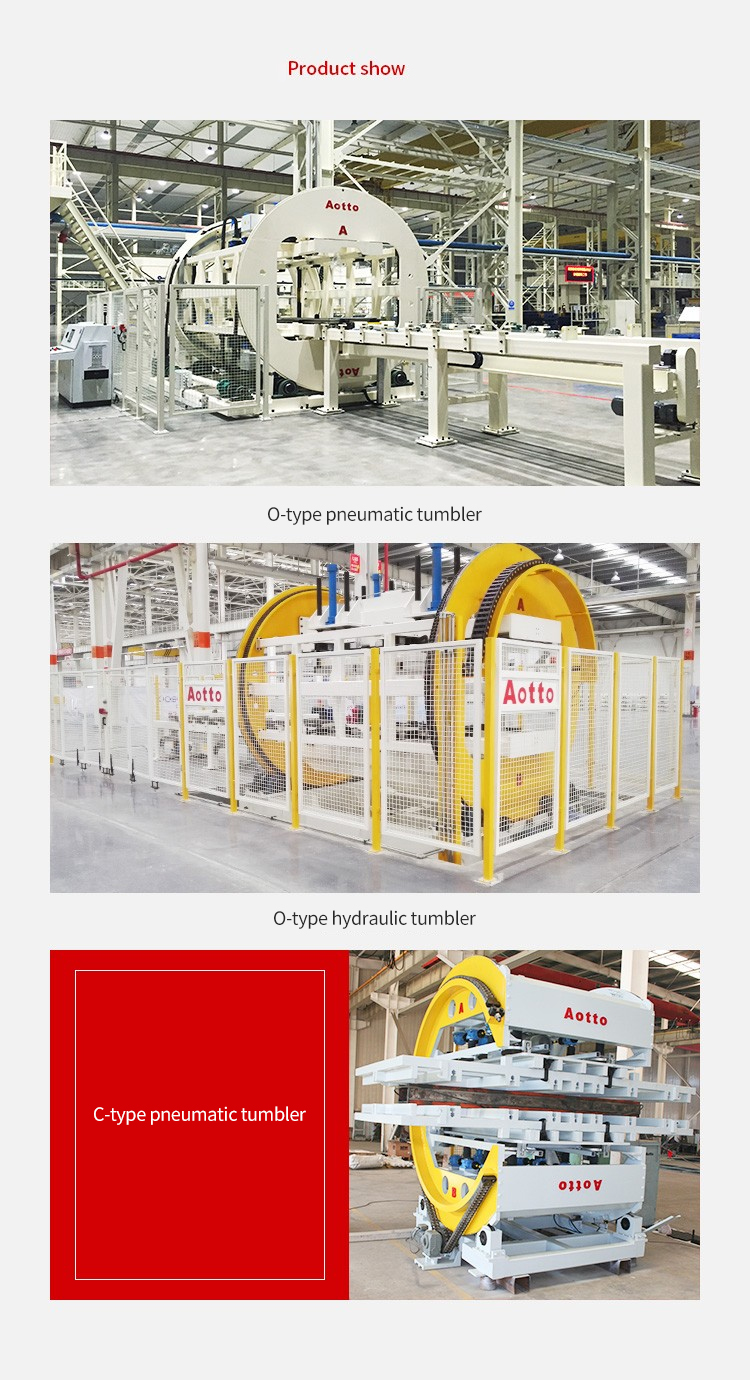

ABT series stack turning machine adopts PLC control and touch screen human-machine interface operation, and has a complete safety protection system and fault diagnosis system. According to the different clamping methods, the equipment can be divided into two types: airbag clamping and hydraulic cylinder clamping. Both clamping methods can automatically adjust the clamping force to prevent the sheet from slipping. The airbag clamping structure has a gentle clamping force, is environmentally friendly and does not pollute the sheet, and is a high-end choice.

According to the user's on-site logistics layout, the ABT series stack turning machine can adapt to various loading methods such as side loading, front and back loading, etc.

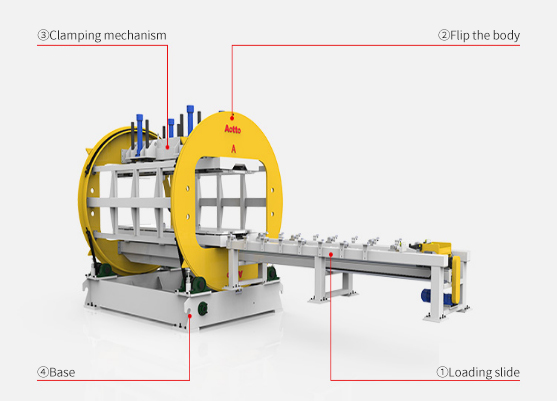

Product structure:

① Loading slide: a powered slide, the power source is a motor reducer, which is used to realize the in and out transportation of the stacking materials; a positioning block is installed on the slide pallet for material rack positioning.

② Turning body: The stacking material turning is driven by a motor reducer with a brake device, and the motor is controlled by a frequency converter. A deceleration switch and a stop switch are set at each end to achieve accurate control of the stacking material turning.

③ Clamping mechanism: The stacking material clamping mechanism is a key component of the turning machine. This stacking material turning machine adopts an advanced clamping scheme, which is stable and reliable. The clamping action is achieved by the oil cylinder driving the movable beam to move up and down, and the components are installed as a whole in the turning machine frame.

④ Base: Safety devices are arranged on both sides of the turning machine base. The safety device is a latch device composed of a cylinder, a latch, a cylinder magnetic switch, etc. When the turning machine is rotated into place, the latch device pushes the latch into the positioning hole. If the turning machine rotates, the latch will be withdrawn from the positioning hole before rotation.