Product IntroductionTransTig/MagicWave Digital TIG WelderThe new TIG welder is a fully digital microprocessor-controlled inverter welder. The digital microprocessor monitors the entire welding process and quickly responds to any changes. The arc of the digital TIG welder is extremely quiet and very stable; the operation is simple and easy to understand, in fact, it can be learned almost without a teacher; the welding power supply uses single-phase or three-phase electricity, which is easy to connect; it is light but very sturdy. The welder can be upgraded with software. Without changing the hardware, the welder can add new functions through software upgrades, and the quality of the welding process can be monitored by computer (such as printing or saving the welding process as a file). These welders have good versatility, and the welding machine accessories can be completely interchangeable and complementary. The fully digital TIG welder is divided into MagicWave AC and DC type and TransTig DC type.

Product Advantages

Wide Application

These TIG welding machines are very suitable for field work. Lightweight, they are the lightest welding machines in the world and can be carried anywhere. The sturdy structural design enables them to work in very harsh field environments. The single-phase power supply design can use the 220 V single-phase power socket available for export. Very suitable for welding aluminum and its alloys, as well as low-alloy steel, high-alloy steel and non-ferrous metals. The standard Localnet Interface interface is easy to connect with the attached JobMaster gun, remote control, etc., and is easy to handle automatic operation and robot connection.

Economy

The MagicWave welder is the shining star of modern new energy-efficient welding machines. Its economy has been fully considered from the beginning of the design. The welder uses high-performance components produced by Fronius, which makes it have a highly efficient welding power supply, extremely low no-load losses and extremely low power consumption. The cooling system (whether it is a water cooling system or a cooling fan) is in economic operation mode, which can be automatically shut down and only run when needed. While reducing costs, noise is also greatly reduced. The MagicWave welder has an automatic "ball-slicing" function, which saves welding preparation time.

Excellent arc striking performance

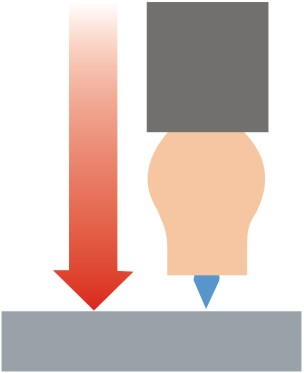

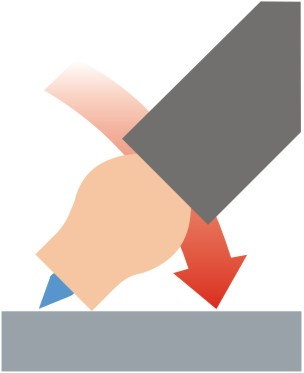

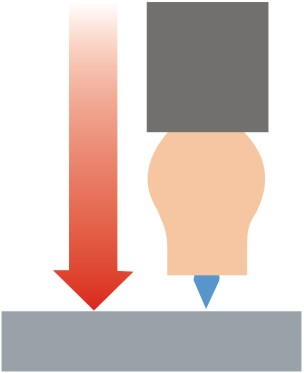

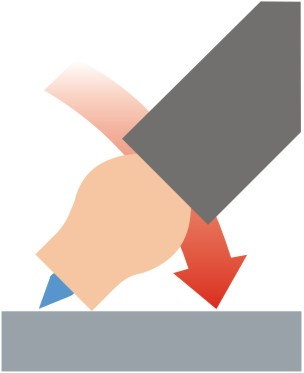

In TIG welding, arc striking plays a vital role. The fully digital series welding machines can both high-frequency arc striking and lifting arc striking. When high-frequency arc striking, as long as the switch is pressed, a high-frequency high-voltage pulse will instantly ignite the arc. Lifting arc striking is particularly suitable for working environments that are not suitable for high-frequency interference. The entire arc striking process with digital precision control ensures that arc striking is easy but will not stick to tungsten.

Arc striking method to avoid high-frequency interference: lifting arc striking

Active Wave

The MagicWave welder can provide a unique AC waveform developed by Fronius. The digital microprocessor (DSP) monitors the welding process in real time and controls the shape of the output waveform, which minimizes the arc noise while being very stable. In addition, the welding process does not require high-frequency arc stabilization, and high-quality welding can still be obtained in sensitive environments where high-frequency interference is not allowed.

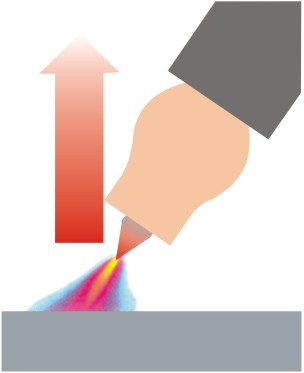

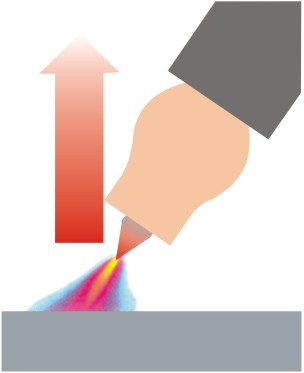

Special aluminum welding program

Due to the special nature of aluminum, Fronius has set up a special aluminum welding program. For example, when welding aluminum with AC TIG, if the tip of the tungsten needle is not sharp, it will produce a defect of incomplete penetration. The MagicWave welder will make the tip of the tungsten needle form a spherical surface to obtain a good root penetration effect. It should be pointed out that this ball cutting function is automatically completed by the welder, which saves a lot of time. All you have to do is to load the tungsten needle into the welding gun and select the tungsten electrode diameter. The welder will automatically control the arc to cut the tip of the tungsten needle into a spherical shape and size you need.

TAC tack welding function

An important preparation before welding is tack welding. So far, the usual tack welding only relies on the slight movement of the welding gun to connect the two molten pools on both sides of the workpiece, but with the "TAC" function, only one molten pool will be formed, and tack welding becomes easy and fast. This is because the spot welding current of "TAC" is pulsating and discontinuous, and the molten pools on both sides of the tack welding quickly form a single molten pool.

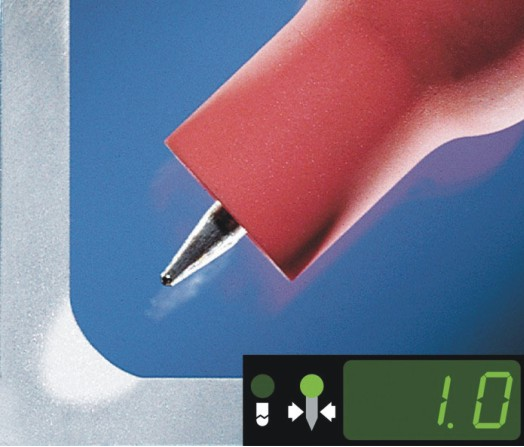

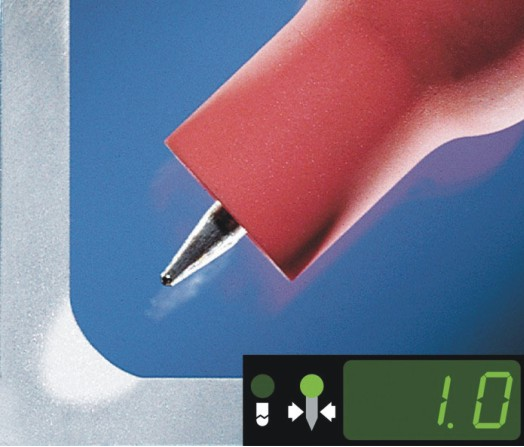

Tungsten electrode tip diameter: 1 mm

Base material: AlMg3

Workpiece thickness: 5 mm

Welding current: 185 A Welding voltage: 15.6 V

AC balance value: -5

Tungsten electrode tip diameter: 3.2 mm

Base material: AlMg3

Workpiece thickness: 5 mm

Welding current: 185 A

Welding voltage: 15.6 V

AC balance value: -0

Cooperative welding of MW AC/DC welding machine

TIG aluminum alloy welding does not open grooves for thin aluminum plates of 8 mm and below, and does not clean the roots of thick aluminum plates of 20 mm and above. With the Fronius MW series digital TIG power supply, it is no longer a problem. This is because the Fronius MW series digital TIG power supply can accurately control the secondary input of the power supply, and can realize two power supplies on the same workpiece, and there is no interference with each other during AC output. During the welding process, the two welding guns are opposite, and one front and one back share a molten pool, which reduces the procedures of back cleaning and back gas protection. At the same time, the welding output current of each of the two power supplies is reduced by half compared with the conventional welding current. Welding deformation, welding porosity, lack of fusion and other welding defects can be most effectively controlled. For thin plate welding, only one welding gun can have filler metal, and both sides will get a more perfect weld.

Safety

Each MagicWave welder has been rigorously tested and meets the following safety standards: [S] mark means it has passed the test standard for preventing electric shock in narrow spaces. [CE] mark means it complies with EN60971-1 and EN50199 standards. The IP 23 protection level can prevent the ingress of objects with a diameter of more than 12 mm and rainwater within a 120° range above the welder, making it suitable for field operations.