Product IntroductionTransSteel Digital Inverter Welding MachineIn the manufacture of steel structures, solidity and reliability are the most important. This requires strong and solid production tools. The same is true for welding steel structures. TransSteel was developed under the guidance of such a design concept: to be a solid and reliable partner, not only can it adapt to various welding requirements intelligently, but also it is very simple to operate. With digital control technology and the best expert program library in the industry, the TransSteel welding system is fully prepared to provide customers with the best carbon steel welding, and can 100% guarantee excellent performance every time.

Product Advantages

Strong and Stable

In the field of steel structure processing, TransSteel can withstand extremely harsh operating environments anywhere. The sturdy structural design makes the equipment "as strong as steel". This system provides power levels of 350A for air cooling and 500A for water cooling, which can be used in manual welding and robot automatic welding.

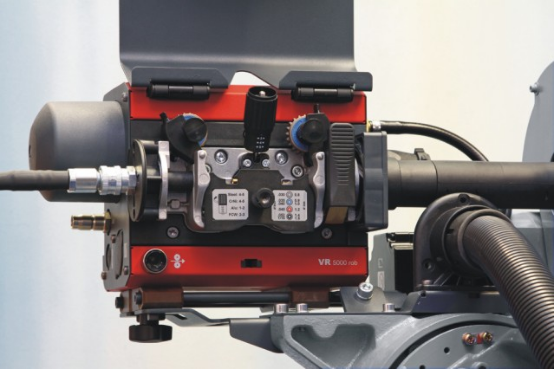

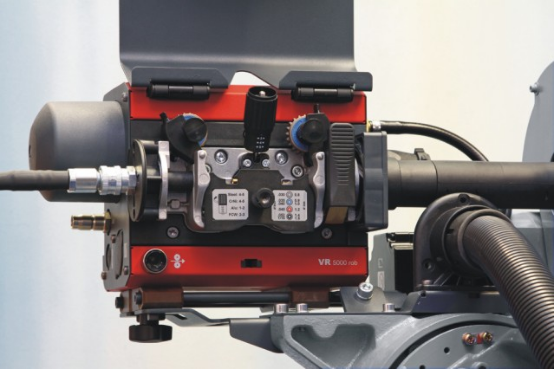

The wire feeder has greater flexibility

The wire feeder is compact, lightweight and easy to carry. This makes the wire feeder more flexible in application, and this structure can also protect the wire feeder from damage caused by collision with the workpiece. The operation panel and all display screens are integrated on the wire feeder, and the operation can be adjusted directly at the welding position. The angled tilt setting of the display panel makes it easier to observe the readings from different positions.

Welding system that provides optimal characteristics in real time

The perfect welding characteristics are reflected in the various stages of the welding process, such as arc initiation, arc burning and arc termination. Steel Transfer technology is an expert program library developed by Fronius for TransSteel welding machines. It adapts to various requirements of carbon steel welding and is divided into three welding modes: Steel Root, Steel Dynamic and Steel, which are used for root welding, filling and general applications respectively.

Economical and practical

The sturdy design concept greatly increases the durability of each component. The dust filter protects the internal components of the welding power source from dust pollution, and the water filter ensures the cleanliness of the circulation system, thereby extending the service life of the entire system. The shell is made of high-strength plastic to prevent the wire feeder from breaking and ensure complete insulation. The temperature-controlled fan only runs when needed, reducing the chance of dust entering the welder.

Safe and reliable

The inclined connection port baffle prevents damage to the welder interface, the relay connector is hidden under the "slide plate" on one side of the wire feeder, and the water tank filling port is protected to prevent mechanical damage. The ground leakage monitoring prevents the welding current from being conducted through the grounding point of the welder and damaging the insulation of the system. It meets many international certification standards.