What types of robot movements are there? What are their functions?

Publish Time: 2024-08-08

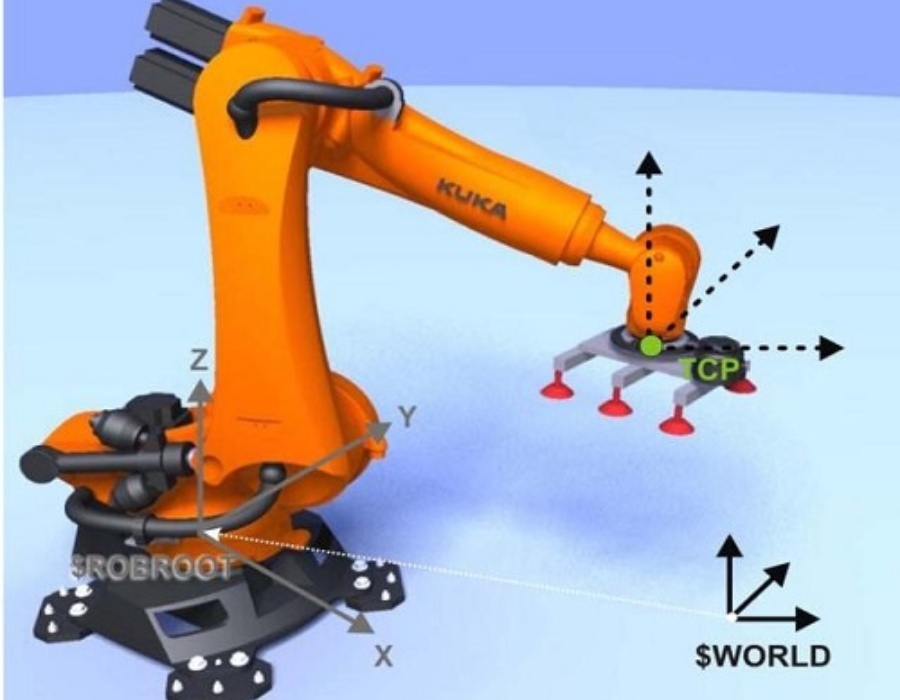

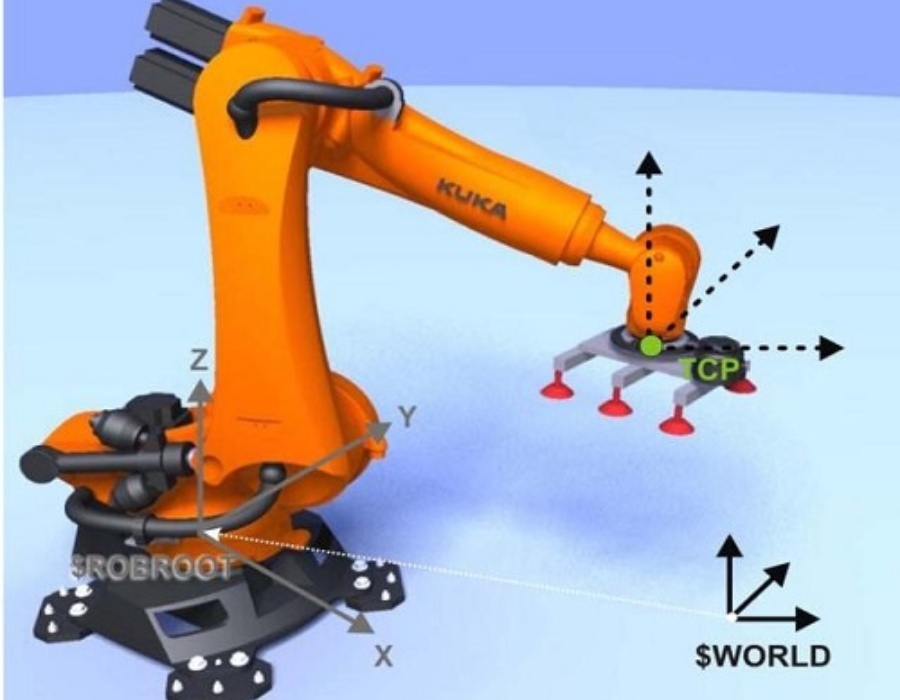

The robot's motion types can be mainly divided into joint motion, linear motion, A arc motion, and C arc motion. Each motion type has its specific function and application scenario: 1. Joint Motion (J):Joint motion is a type of motion in which the robot moves to a specified position by independently controlling the angles of each joint axis. In joint motion, the robot does not care about the trajectory from the starting point to the target point, but directly adjusts the angles of each axis to reach the target position.Function: Joint motion is suitable for situations where the robot needs to be moved quickly to a certain position without considering the path. It is often used for positioning the robot before starting precise work or in rough positioning situations where the trajectory does not need to be controlled.2. Linear Motion (L):Linear motion refers to the type of motion in which the robot moves from one point to another accurately along a straight path. In linear motion, the robot tool end (TCP) moves along a straight trajectory, even if the trajectory is nonlinear in the joint space.Function: Linear motion is often used in situations where precise operations along a straight path are required, such as welding, cutting, painting, etc., because these operations often require the end of the tool to maintain a constant direction and position relationship on the work surface.3.Arc Motion (A):Arc motion refers to a way of performing circular motion through an intermediate point (transition point). In this type of motion, the robot moves from the starting point to a transition point, and then draws an arc from the transition point to the end point.Function: A arc motion is often used in situations where circular path control is required, such as certain welding and grinding tasks, where the selection of transition points can optimize motion smoothness and speed.4.C Circular Arc Motion (C):C circular motion is a circular motion completed by defining the starting point, end point and an additional point (passing point) on the arc. This method can control the arc path more accurately because it does not need to rely on transition points like A arc motion.Function: C arc motion is also suitable for operations that require arc trajectories, but compared to A arc motion, it can provide more precise arc control and is suitable for precision machining tasks that have strict requirements on arc paths. Each type of motion has its specific advantages and applicable scenarios. When programming the robot, it is necessary to select the appropriate type of motion according to the specific application requirements.Joint motion is suitable for rapid positioning, while linear motion and circular motion are suitable for precise operations that require path control. By combining these types of motion, the robot can complete complex task sequences and achieve high-precision automated production.

1. Joint Motion (J):Joint motion is a type of motion in which the robot moves to a specified position by independently controlling the angles of each joint axis. In joint motion, the robot does not care about the trajectory from the starting point to the target point, but directly adjusts the angles of each axis to reach the target position.Function: Joint motion is suitable for situations where the robot needs to be moved quickly to a certain position without considering the path. It is often used for positioning the robot before starting precise work or in rough positioning situations where the trajectory does not need to be controlled.2. Linear Motion (L):Linear motion refers to the type of motion in which the robot moves from one point to another accurately along a straight path. In linear motion, the robot tool end (TCP) moves along a straight trajectory, even if the trajectory is nonlinear in the joint space.Function: Linear motion is often used in situations where precise operations along a straight path are required, such as welding, cutting, painting, etc., because these operations often require the end of the tool to maintain a constant direction and position relationship on the work surface.3.Arc Motion (A):Arc motion refers to a way of performing circular motion through an intermediate point (transition point). In this type of motion, the robot moves from the starting point to a transition point, and then draws an arc from the transition point to the end point.Function: A arc motion is often used in situations where circular path control is required, such as certain welding and grinding tasks, where the selection of transition points can optimize motion smoothness and speed.4.C Circular Arc Motion (C):C circular motion is a circular motion completed by defining the starting point, end point and an additional point (passing point) on the arc. This method can control the arc path more accurately because it does not need to rely on transition points like A arc motion.Function: C arc motion is also suitable for operations that require arc trajectories, but compared to A arc motion, it can provide more precise arc control and is suitable for precision machining tasks that have strict requirements on arc paths. Each type of motion has its specific advantages and applicable scenarios. When programming the robot, it is necessary to select the appropriate type of motion according to the specific application requirements.Joint motion is suitable for rapid positioning, while linear motion and circular motion are suitable for precise operations that require path control. By combining these types of motion, the robot can complete complex task sequences and achieve high-precision automated production.