What are the types of robotic grinding and polishing equipment? What are their characteristics?

Publish Time: 2024-06-20

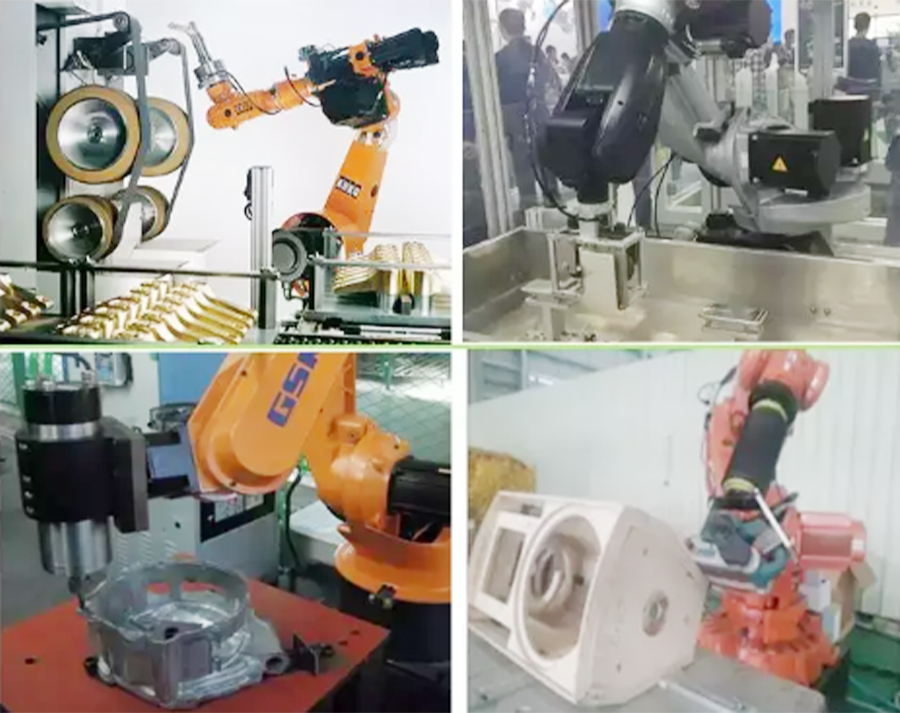

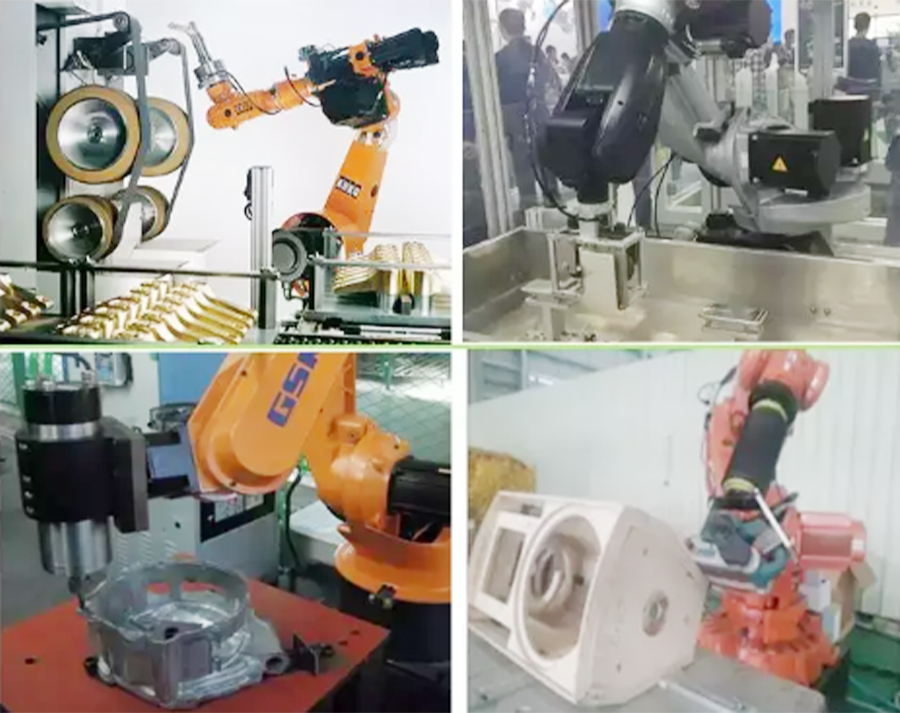

Robotic grinding and polishing equipment has various product types, designed to meet the specific needs of different industries and workpieces. The following is an overview of some of the main product types and how to use them: Product type:1. Articulated robot grinding system:●Features: It has high degrees of freedom and can perform complex trajectory movements. It is suitable for grinding workpieces of various shapes and sizes.●Application: Widely used in automobiles, aerospace, furniture and other fields.2. Linear/SCARA robot grinder:●Features: Simple structure, fast speed, suitable for grinding operations on planes or straight paths.●Application: Suitable for high-efficiency grinding of flat plates, plates, and linear surfaces.3. Force-controlled grinding robot:●Features: Integrated force sensor, which can automatically adjust the grinding force according to changes in the workpiece surface to ensure processing quality.●Application: Precision processing, such as molds, medical devices, etc., where precise force control is required.4. Vision-guided robot:●Features: Combined with machine vision technology, it realizes automatic identification, positioning and path planning of workpieces.●Application: Suitable for disorderly arrangement grinding of complex-shaped workpieces to improve processing accuracy.5. Special grinding robot workstation:●Features: Integrated grinding tools, dust removal system, workbench, etc. to form a complete automated grinding unit.●Application: Designed for specific tasks, such as wind turbine blades, automobile body grinding, etc.6. Handheld robot grinding tool:●Features: Flexible operation, human-machine collaboration, suitable for small batches and complex workpieces.●Application: Crafts, repair operations and other occasions that require high operational flexibility.How to use:1. System integration and configuration:●Select the appropriate robot type according to the characteristics of the workpiece, and configure the corresponding grinding tools, end effectors, force control systems and visual systems, etc.2. Programming and debugging:●Use robot programming software (such as ABB's RobotStudio, FANUC's Robot Guide, etc.) for path planning and motion programming.●Perform simulation verification to ensure that the program has no collision and the path is correct.3. Installation and calibration:●Install the robot and supporting equipment to ensure that the robot base is stable and the workpiece is accurately positioned.●Perform zero-point calibration on the robot to ensure accuracy.4. Safety settings:●Configure safety fences, emergency stop buttons, safety light curtains, etc. to ensure the safety of operators.5. Operation and monitoring:●Start the robot program and perform actual grinding operations.●Use the teach pendant or remote monitoring system to monitor the operation status in real time and adjust parameters as needed.6. Maintenance and optimization:●Regularly check robot joints, tool heads, sensors and other components, and perform necessary maintenance and replacement.●Analyze operation data, optimize programs and parameters, and improve efficiency and quality.Through the above steps, the robot grinding and polishing equipment can efficiently and accurately complete the surface treatment of workpieces, improve production efficiency and product quality.

Product type:1. Articulated robot grinding system:●Features: It has high degrees of freedom and can perform complex trajectory movements. It is suitable for grinding workpieces of various shapes and sizes.●Application: Widely used in automobiles, aerospace, furniture and other fields.2. Linear/SCARA robot grinder:●Features: Simple structure, fast speed, suitable for grinding operations on planes or straight paths.●Application: Suitable for high-efficiency grinding of flat plates, plates, and linear surfaces.3. Force-controlled grinding robot:●Features: Integrated force sensor, which can automatically adjust the grinding force according to changes in the workpiece surface to ensure processing quality.●Application: Precision processing, such as molds, medical devices, etc., where precise force control is required.4. Vision-guided robot:●Features: Combined with machine vision technology, it realizes automatic identification, positioning and path planning of workpieces.●Application: Suitable for disorderly arrangement grinding of complex-shaped workpieces to improve processing accuracy.5. Special grinding robot workstation:●Features: Integrated grinding tools, dust removal system, workbench, etc. to form a complete automated grinding unit.●Application: Designed for specific tasks, such as wind turbine blades, automobile body grinding, etc.6. Handheld robot grinding tool:●Features: Flexible operation, human-machine collaboration, suitable for small batches and complex workpieces.●Application: Crafts, repair operations and other occasions that require high operational flexibility.How to use:1. System integration and configuration:●Select the appropriate robot type according to the characteristics of the workpiece, and configure the corresponding grinding tools, end effectors, force control systems and visual systems, etc.2. Programming and debugging:●Use robot programming software (such as ABB's RobotStudio, FANUC's Robot Guide, etc.) for path planning and motion programming.●Perform simulation verification to ensure that the program has no collision and the path is correct.3. Installation and calibration:●Install the robot and supporting equipment to ensure that the robot base is stable and the workpiece is accurately positioned.●Perform zero-point calibration on the robot to ensure accuracy.4. Safety settings:●Configure safety fences, emergency stop buttons, safety light curtains, etc. to ensure the safety of operators.5. Operation and monitoring:●Start the robot program and perform actual grinding operations.●Use the teach pendant or remote monitoring system to monitor the operation status in real time and adjust parameters as needed.6. Maintenance and optimization:●Regularly check robot joints, tool heads, sensors and other components, and perform necessary maintenance and replacement.●Analyze operation data, optimize programs and parameters, and improve efficiency and quality.Through the above steps, the robot grinding and polishing equipment can efficiently and accurately complete the surface treatment of workpieces, improve production efficiency and product quality.