Robotic palletizing automation process? Its application areas?

Publish Time: 2024-04-09

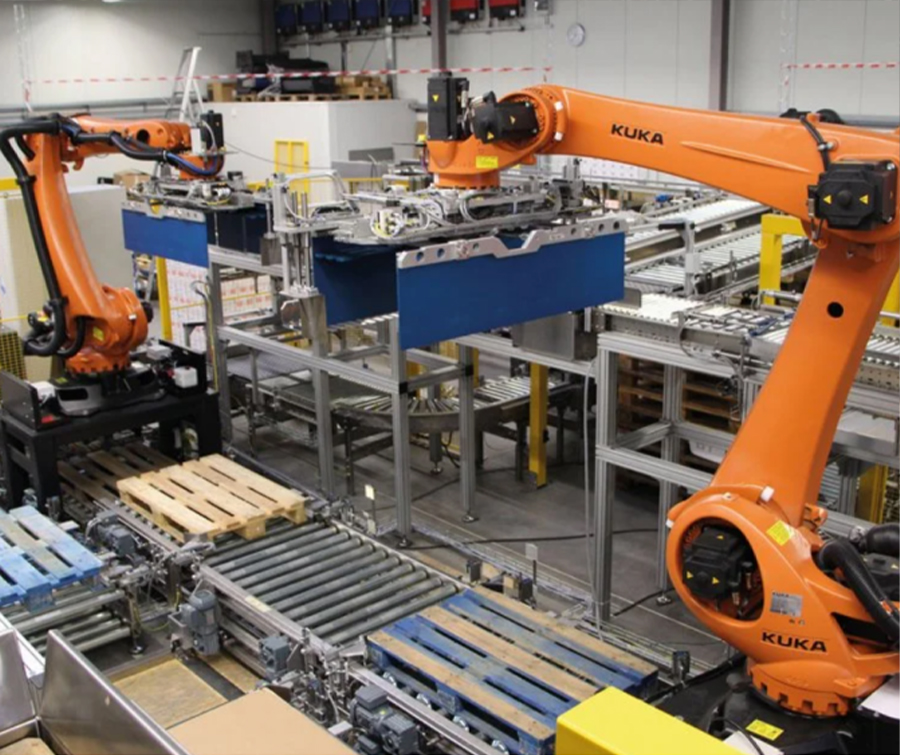

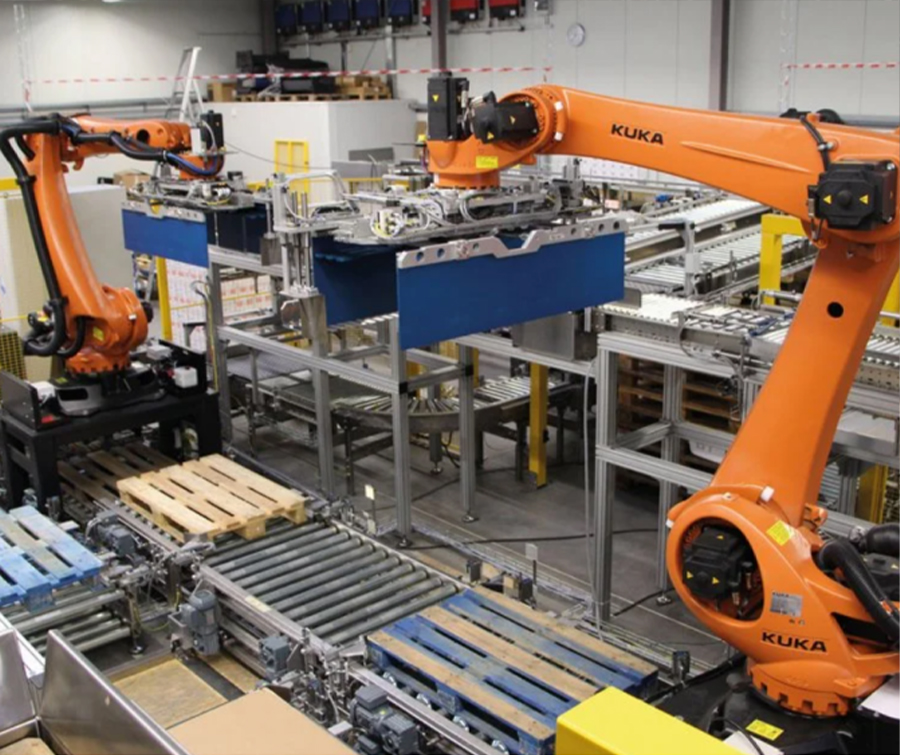

Robotic palletizing automation refers to the process of using industrial robots and related auxiliary equipment to automatically grab, transport and stack goods produced on the production line onto pallets according to preset rules. This automation solution is designed to improve production efficiency, reduce manual labor intensity, reduce error rates, improve space utilization and logistics management levels. The specific implementation process includes: 1. Material identification and positioning: Identify and position materials to be palletized through technologies such as sensors and vision systems.2. Robot grabbing: The robot accurately grabs materials through end effectors (such as grippers, suction cups, etc.) according to the preset program.3. Material handling: The robot moves the grabbed materials to the pallet area according to the designated path.4. Pallet management: The pallet conveying system delivers the empty pallets to the designated location, and the robot automatically stacks the materials.5. Palletizing strategy: The robot stacks materials layer by layer on the pallet according to the preset palletizing mode, ensuring that the palletizing is stable, compact and meets transportation requirements.6. Fully loaded pallets out of the warehouse: When the pallets are palletized, the robot or associated conveyor system will send the full pallets to the storage area or directly load them into the transport vehicle.7. Monitoring and feedback: The entire process can be monitored in real time through the control system and dynamically adjusted according to production needs to achieve intelligent optimization.8. Safety protection: The system is equipped with necessary safety equipment, such as safety fences, photoelectric sensors, emergency stop buttons, etc., to ensure the safety of personnel and equipment during the operation of the robot.Robotic palletizing automation is widely used in many industries, such as food and beverage, pharmaceutical, chemical, logistics, manufacturing, etc. It is one of the important links in realizing industrial automation and intelligent production.Robotic palletizing automation technology is widely used in multiple manufacturing and logistics warehousing fields, the most common of which include:1.Manufacturing industry:•Food and beverage industry: At the end of the filling and packaging production line, palletizing robots neatly stack boxes of beverages, food and other products on pallets according to specific patterns.•Chemical industry: Used for transporting and palletizing heavy objects such as various chemical products, chemical raw material barrels, and bagged fertilizers.•Pharmaceutical industry: Automatically palletize the outer packaging boxes of pharmaceutical products, such as medicines, medical devices, etc.•Auto parts industry: classifying, arranging and palletizing auto parts.2. Logistics and warehousing:•Warehouses and distribution centers: During the process of goods entering and exiting the warehouse, robots automatically complete the palletizing and depalletizing of parcels, cartons and other goods.•Postal express industry: In the sorting center, robots can assist in palletizing a large number of express packages.

1. Material identification and positioning: Identify and position materials to be palletized through technologies such as sensors and vision systems.2. Robot grabbing: The robot accurately grabs materials through end effectors (such as grippers, suction cups, etc.) according to the preset program.3. Material handling: The robot moves the grabbed materials to the pallet area according to the designated path.4. Pallet management: The pallet conveying system delivers the empty pallets to the designated location, and the robot automatically stacks the materials.5. Palletizing strategy: The robot stacks materials layer by layer on the pallet according to the preset palletizing mode, ensuring that the palletizing is stable, compact and meets transportation requirements.6. Fully loaded pallets out of the warehouse: When the pallets are palletized, the robot or associated conveyor system will send the full pallets to the storage area or directly load them into the transport vehicle.7. Monitoring and feedback: The entire process can be monitored in real time through the control system and dynamically adjusted according to production needs to achieve intelligent optimization.8. Safety protection: The system is equipped with necessary safety equipment, such as safety fences, photoelectric sensors, emergency stop buttons, etc., to ensure the safety of personnel and equipment during the operation of the robot.Robotic palletizing automation is widely used in many industries, such as food and beverage, pharmaceutical, chemical, logistics, manufacturing, etc. It is one of the important links in realizing industrial automation and intelligent production.Robotic palletizing automation technology is widely used in multiple manufacturing and logistics warehousing fields, the most common of which include:1.Manufacturing industry:•Food and beverage industry: At the end of the filling and packaging production line, palletizing robots neatly stack boxes of beverages, food and other products on pallets according to specific patterns.•Chemical industry: Used for transporting and palletizing heavy objects such as various chemical products, chemical raw material barrels, and bagged fertilizers.•Pharmaceutical industry: Automatically palletize the outer packaging boxes of pharmaceutical products, such as medicines, medical devices, etc.•Auto parts industry: classifying, arranging and palletizing auto parts.2. Logistics and warehousing:•Warehouses and distribution centers: During the process of goods entering and exiting the warehouse, robots automatically complete the palletizing and depalletizing of parcels, cartons and other goods.•Postal express industry: In the sorting center, robots can assist in palletizing a large number of express packages. 3. Packaging industry:•Carry out automated, efficient and standardized palletizing of various types of packaged goods to improve storage and transportation efficiency.4. Building materials industry:•Automated stacking and palletizing of building materials such as bricks, wood, stone, and boards.5. Agriculture and animal husbandry:•Automated palletizing of packaged products in agricultural products processing and animal feed production.6. Tobacco industry:•Automated packaging and palletizing of tobacco products.7. E-commerce and retail industry:•In e-commerce warehouses, robotic palletizing automation is used to improve order fulfillment speed and warehouse space utilization. In short, any scenario involving a large number of items that need to be stacked efficiently and accurately according to certain rules has room for application of robotic palletizing automation.Through this technology, production efficiency can be significantly improved, manual labor intensity reduced, work safety improved, and adaptability to changing market demands.

3. Packaging industry:•Carry out automated, efficient and standardized palletizing of various types of packaged goods to improve storage and transportation efficiency.4. Building materials industry:•Automated stacking and palletizing of building materials such as bricks, wood, stone, and boards.5. Agriculture and animal husbandry:•Automated palletizing of packaged products in agricultural products processing and animal feed production.6. Tobacco industry:•Automated packaging and palletizing of tobacco products.7. E-commerce and retail industry:•In e-commerce warehouses, robotic palletizing automation is used to improve order fulfillment speed and warehouse space utilization. In short, any scenario involving a large number of items that need to be stacked efficiently and accurately according to certain rules has room for application of robotic palletizing automation.Through this technology, production efficiency can be significantly improved, manual labor intensity reduced, work safety improved, and adaptability to changing market demands.